Service Parts Demand Forecasting

Automated 52-week SKU forecasting with ensemble models achieving ≤8% MAPE accuracy, reducing inventory by 20% and stockouts by 40%.

Challenge

Service teams must forecast thousands of SKUs across regions and stocking locations. Planners juggle ERP reports, spreadsheets, and siloed systems while demand shifts with seasonality, install base growth, warranty mix, and failure spikes. Traditional single model approaches miss multivariate, non linear patterns, driving excess inventory, stockouts, and tied up working capital.

The objective: Auto generate 52 week SKU location forecasts; maintain ≤8% MAPE for A class SKUs (≤12% for B and C); reduce stockouts ≥40% and on hand inventory ≥15%, with auditable ERP and WMS updates.

Solution: How AIP changed the operating model

Learning and setup

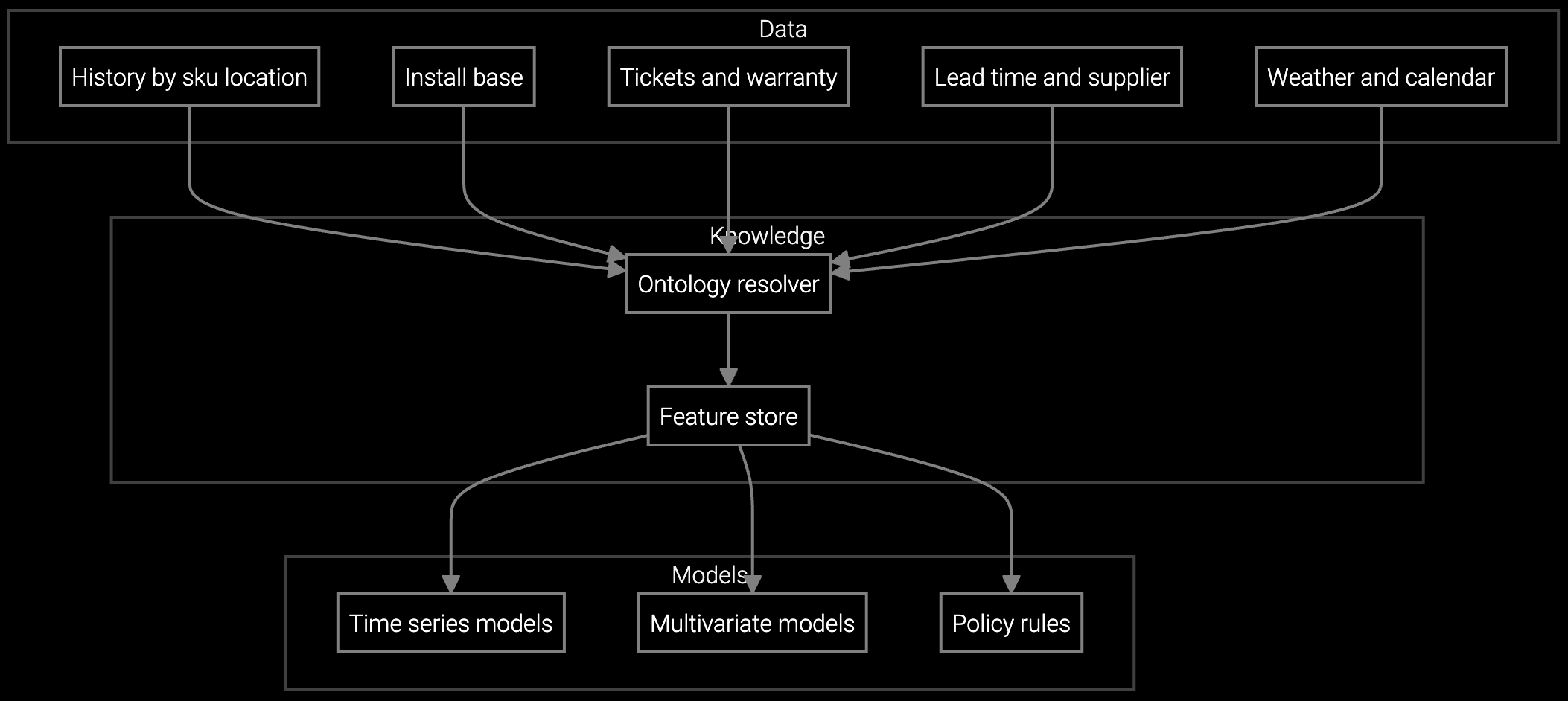

Powered by the Aftermarket Intelligence Platform (AIP), the agentic solution applied its forecasting, predictive, and policy models. Training data came from historical consumption and orders by SKU and location, install base and asset history, service tickets and failure codes, warranty claims, supplier lead times, prices and promotions, business calendars and seasonality, weather and macro indicators, and part supersession and BOM mappings. This enabled the AI agent to recognize and interpret part IDs, locations, equipment models, install base counts, lead times, min max targets, service levels, open POs and backorders, warranty status, price, season flags, and supersession links. *(Diagram placement: Training diagram)*

Workflow orchestration

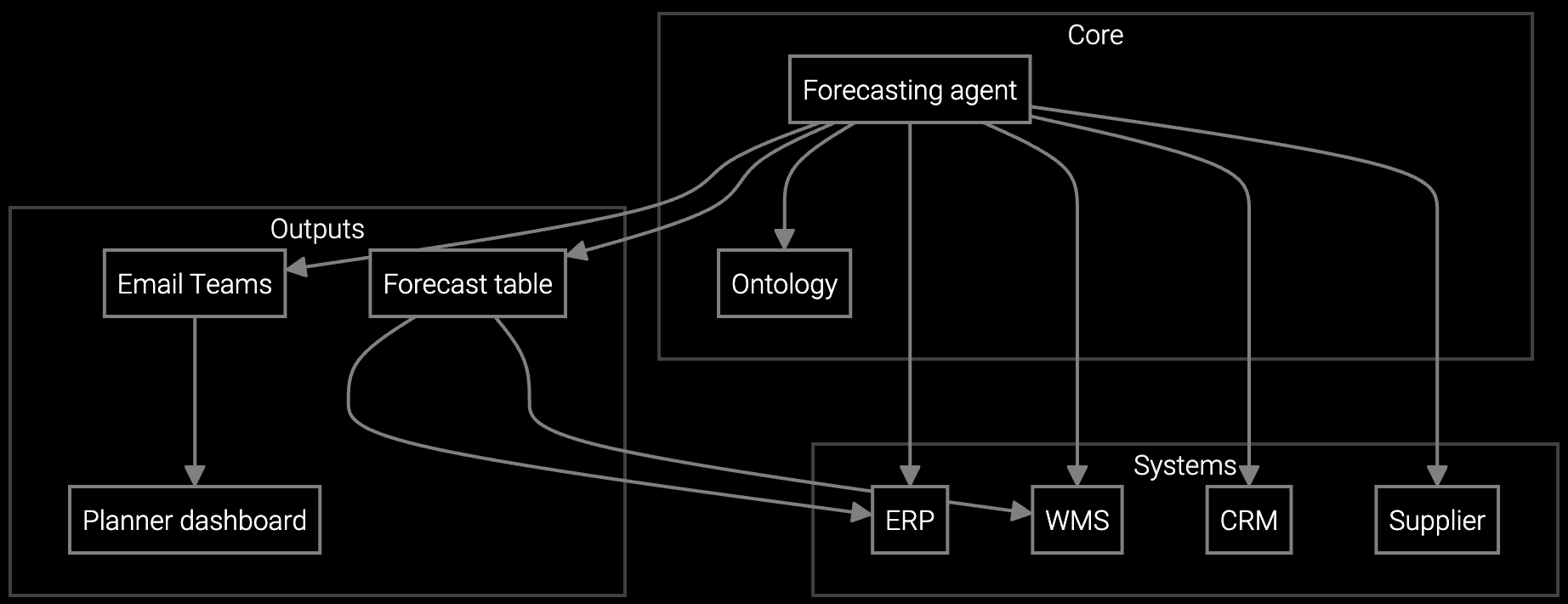

The AI agent analyzes weekly triggers, segments SKUs by class and location, and determines the correct path: clean data, engineer features, backtest candidates, select or ensemble winners, and write forecasts and inventory targets. It navigates ERP, WMS, CRM service history, and supplier portals, mirroring planner steps. Orchestration logic branches when rules apply, for example for cold start parts, supersession chains, sudden failure spikes, or lead time changes, while enforcing governance and audit at every step. *(Diagram placement: Solution architecture diagram)*

Execution and resolution

The AI agent executes each step end to end: data prep, feature engineering, rolling backtests by SKU location, auto selection or ensemble, generation of 52 week forecasts with intervals, top down and bottom up reconciliation, safety stock and reorder point calculation, and replenishment recommendations. Results post in minutes, with updates written to ERP and WMS and notifications sent to planners and dashboards. Exceptions such as data gaps, new part launches, abnormal spikes, or model drift are routed to planners with full context and what if simulations. (Diagram placement: Workflow execution diagram)*