Repair vs Replace Determination

Automated repair vs replace recommendations that complete in under 5 minutes, reducing cost to serve by 15% and increasing replacement conversion by 8-12%.

Challenge

Service teams and customers face uncertainty when deciding to repair or replace appliances. Agents jump between CRM, ERP, parts portals, and ecommerce sites to check costs, lead times, and policies. Each decision takes 20–45 minutes, varies by agent, and often leads to follow up visits when parts are back ordered or travel constraints apply. The absence of a unified decision engine raises cost to serve, slows resolution, and frustrates customers.

The objective: auto recommend repair or replacement for ≥60% of eligible cases with explainable, policy compliant outcomes; reduce time to decision to under 5 minutes; keep post outcome cost variance ≤10%; lift OEM replacement conversion by ≥8%.

Solution: How AIP changed the operating model

Learning and setup

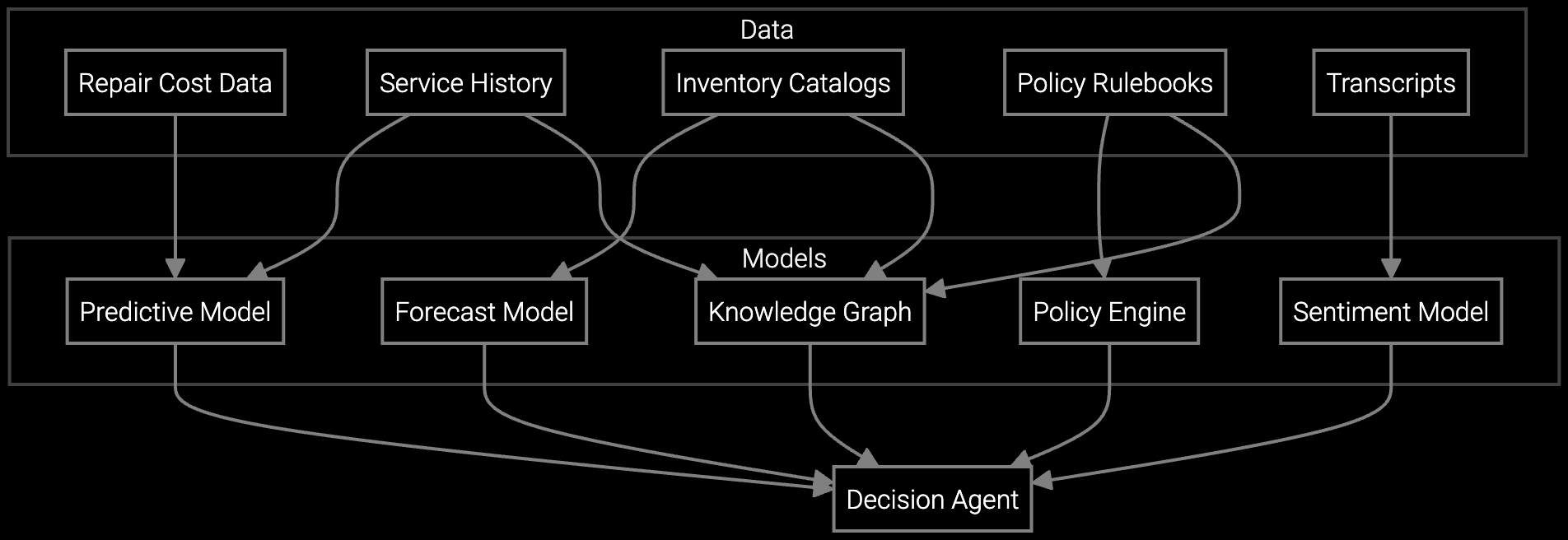

Powered by the Aftermarket Intelligence Platform, the agentic solution applied its predictive model for repair cost, forecasting model for parts lead time, policy engine for compliance, sentiment model for customer intent, and knowledge graph reasoning for context. Training data came from historical repair costs and cycle times, past repair versus replace outcomes, serial level service history, warranty and policy rulebooks, OEM inventory catalogs with pricing and lead times, agent SOPs, and labeled email chat call transcripts. This enabled the AI agent to recognize device model and serial, install date and age, symptoms and failure codes, labor rates and hours, technician travel time, part SKUs with price and ETA, warranty status and thresholds, sentiment score, location code, and compatible replacement SKUs with promotions and fees. *(Diagram placement: Training diagram)*

Workflow orchestration

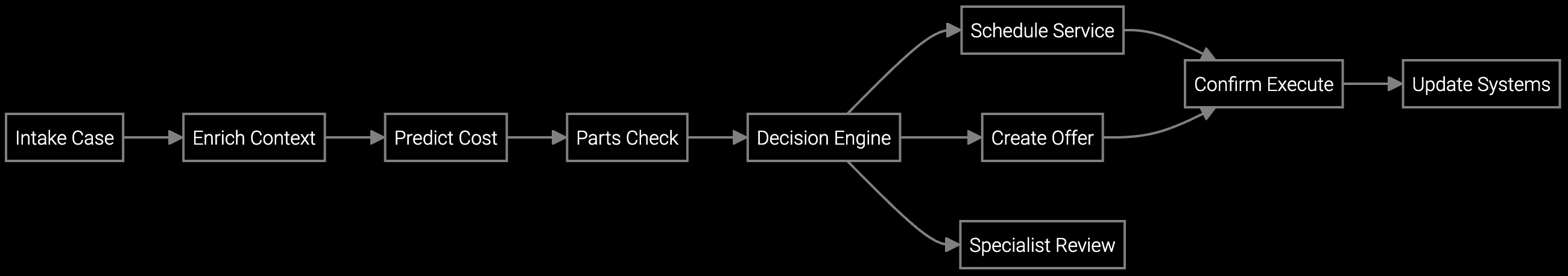

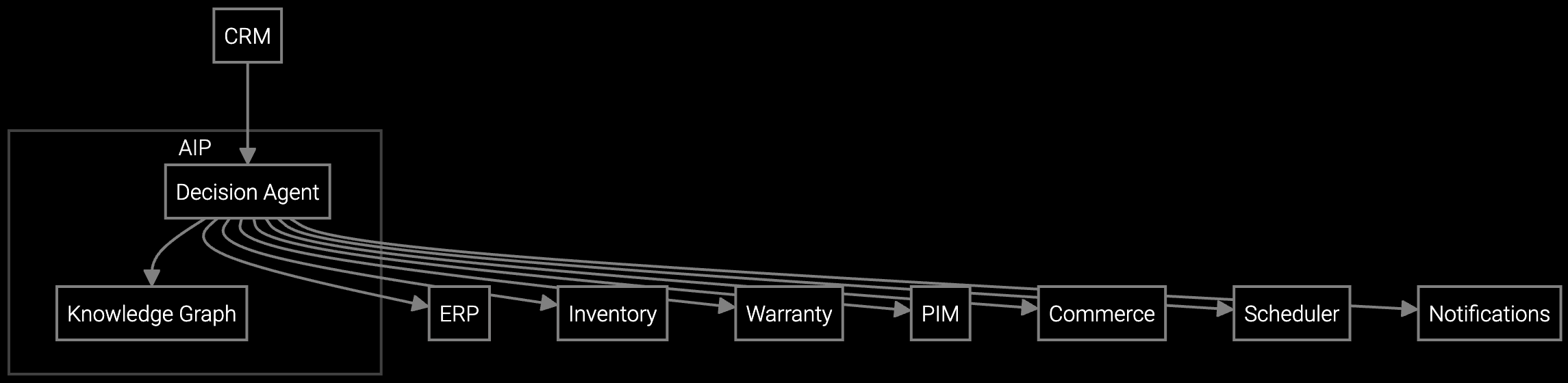

The AI agent reads the case from CRM, extracts identifiers, and determines the correct path. It enriches context via the ontology, queries ERP and inventory for pricing and stock, forecasts lead times, and evaluates warranty and policy thresholds. Orchestration branches when rules apply—for example, if parts lead time exceeds policy, travel time exceeds limit, or sentiment is negative with high repair risk—while ensuring compliance at every step. It also fetches compatible replacements from PIM and commerce when replace is favored. *(Diagram placement: Solution architecture diagram)*

Execution and resolution

The AI agent predicts repair cost and turnaround, simulates back order and travel scenarios, and compares repair total cost with replacement options. It shortlists compatible replacements, presents side by side choices with availability, price, warranty, and purchase links, captures consent, and then creates an order or service job, arranges haul away or RMA, and posts updates across systems. Decisions complete in minutes, with full rationale and an audit trail. Exceptions such as missing serial, no compatible stock, rural travel limits, or low confidence are routed to specialists with context attached. *(Diagram placement: Workflow execution diagram)*