How can service and support teams leverage digital twin technology?

As manufacturers strive to achieve better customer experience throughout the product lifecycle, digital twin technology provides the critical insights that post-sales teams need to enhance their capabilities while reducing costs.

By Andy Chinmulgund

Last month, we discussed how digital twin technology can help manufacturers improve their customer service capabilities. In this post, we’ll look at areas of a typical service organization where this technology can have meaningful impact.

Digital twin technology is not a silver bullet

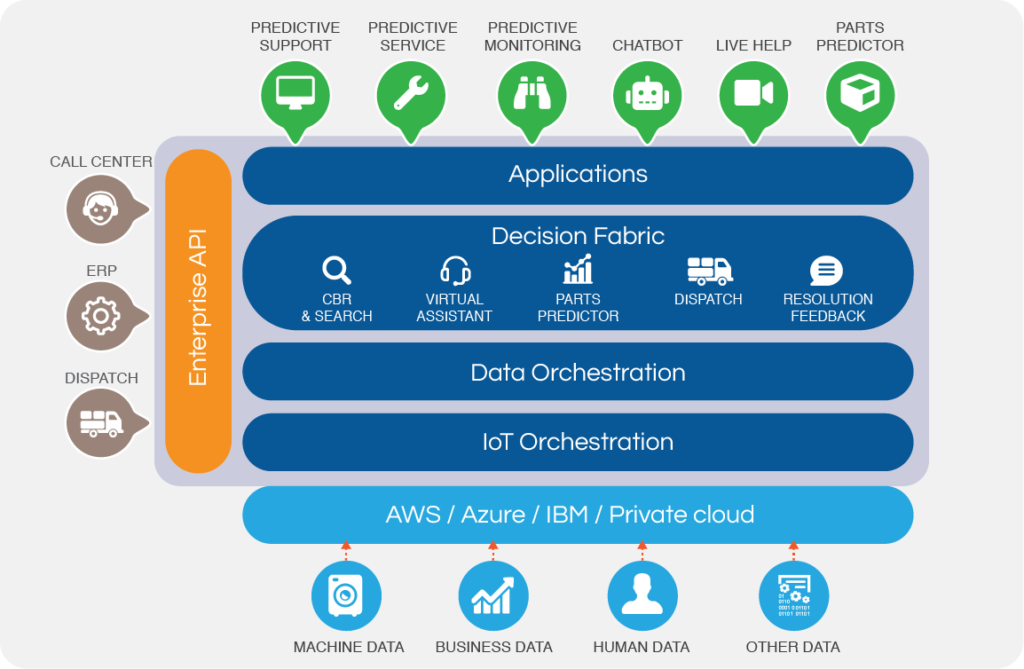

Before we get started, it’s important to understand that digital twin technology is best applied as an enhancement to existing enterprise technologies. That’s because, in order to be useful, it requires critical data from other processes and departments. For example, for the digital twin to accurately represent a product, it needs product-specific data from the PLM system such as CAD engineering and design specifications, information about failure mode and effects, and real-time operational data from on board any in-field unit. As well, the Bruviti system examines operational and maintenance history from the ERP and CRM systems to form an accurate picture of the product’s performance.

By integrating all this disparate data and then applying machine-learning technology, we can form an accurate digital representation of a specific product (that is, identified by its serial number) at a specific customer location. Then, when we add current performance and diagnostic information to the model we can evaluate the current health of that product. And by supplementing this information with usage reports, environmental factors, service intervals, and customer observations, we can model how we might expect this unit to perform in the future.

This detailed representation of the product in the form of a digital twin yields incredibly useful information for support and service organizations.

Bruviti digital twin technology shapes service decisions

With these various data sources integrated and orchestrated, the Bruviti digital twin provides a dynamic digital representation of the physical equipment, its attributes, and associated data. Manufacturers can implement this technology to accelerate product design and improve manufacturing and supply chain functions. Similarly, it enables the optimization of machine deployment, support, and service functions.

Service and support groups can derive particularly useful benefits from these analyses. For in-field equipment, they can track service aspects such as its operational and maintenance history. Then, by applying a range of simple as well as sophisticated machine-learning and statistical models, they can monitor performance, diagnose issues, and recommend solutions to minimize customer downtime.

Here are some real-world examples of how Bruviti digital twin technology is equipping service and support groups to reduce costs and deliver better customer service.

- Parts predictor

- Use historical warranty claims data to accurately predict the parts needed to rectify a service ticket.

- Ensure in-field technician is dispatched to the customer with the correct parts and tools.

- Fault predictor

- Use data from connected sensors to predict a failure that will result in downtime.

- Proactively alert customers that a preventive service intervention is needed.

- Product performance and issue monitoring

- Analyze data from installed machines to identify commonly occurring service issues.

- Provide the engineering team with information that can inform design changes.

- Evaluation of third-party service partners

- For those manufacturers that use external service partners, the Bruviti can provide useful insights for evaluation of the effectiveness of their service. For example, the data may reveal that for certain types of repairs performed by specific technicians result in the recurrence of those faults. Or that when a specific partner installs an appliances, those appliances are more likely to manifest particular faults. These analyses can identify specific training needs for these service partners.

The path from reactive to predictive service

Today, most service organizations today are optimized for delivering excellent reactive service. But what customers really want is predictive service—an alert that something’s about to go wrong *before* it goes wrong. Digital twin technology gets us there; by applying advanced analytics and the power of AI, we can deliver a range of powerful service-oriented applications for our customers, including predictive support, predictive service, predictive monitoring, intelligent chatbots, and knowledge-infused help for both customer self-service and agent dashboards. Are you ready?