Reduce truck rolls to boost field-service productivity and improve customer experience

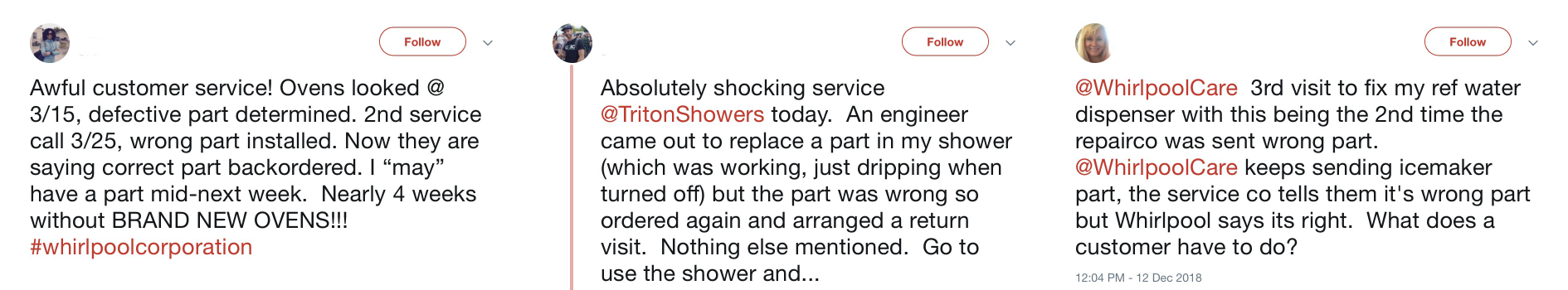

Whether you are a manufacturer of home appliances or commercial equipment, your customers expect fast, reliable, and efficient service. These days, customer expectations are extremely high, and no manufacturer can afford to waste a customer’s time with service calls that don’t fix the product. However, this happens a lot. Just look at these tweets from unhappy customers.

Why does this happen? Let’s look at a classic customer journey. When customers call the contact center to report a product problem, they are frustrated and anxious. They expect the CSR to quickly diagnose the problem and figure out how to get it fixed. All too often, the agent is unable to resolve the issue immediately, which results in the agent scheduling a call from the service team without fully understanding the problem.

This means the service team is flying blind when they call the customer to confirm the service visit. The service rep who’s been assigned the ticket may not be fully aware of the root cause of the issue and may not have a complete service history and details of what parts have been used in the past to fix this issue. It may not even be clear at this point what parts may be needed to resolve this ticket.

Next step: a service call is scheduled, which means a truck roll is set up. In fact, more than one truck roll will be needed, because the service tech must first visit the customer location to understand the issue and determine which need parts to be replaced; and then a return visit to (we hope) fix the problem.

You’re probably thinking this is getting expensive. Indeed, a truck roll costs somewhere between $250 and $400 — adding up to millions of dollars annually for some manufacturers. And, as we see on Twitter, the customer frustration of repeat visits by a field technician means equipment downtime, time off work, and even financial loss, which all take a toll on customer experience.

Manufacturers struggle with information silos

If we examine the problem closely, lack of information is the root cause that costs organizations millions of dollars in truck roll costs. That, plus the use of different systems for the call center and the service group.

Contact center agents need better tools to accurately diagnose the problem, access to detailed customer information, and access to equipment service history. With the right tools, they can schedule service calls through expert-guided tools to quickly troubleshoot and provide DIY solutions for simple issues.

For more complex issues where a visit by a service technician is needed, it is important that field technicians are furnished with information that provides an in-depth understanding of the problem so that the right parts are loaded to solve the issue quickly and efficiently.

While having the relevant information is critical it is also important to have the information on a unified platform that is accessible by both teams. With the objective of reducing truck roll costs and improving the customer experience, let’s identify what information we need and why we need it.

- Customer information

The caller’s personal details such as name, email, phone, etc. enables caller verification and scheduling of a service call. - Equipment information

Detailed product/equipment information (model, serial number, etc.) enables the agent to determine whether or not the device has been registered and is covered under warranty. This also helps the agent get details of common service issues and parts used, and to determine if it’s a recurring problem related to design, user operation, or external factors such as weather. - Service information

Having access to a product’s service history helps the service teams be better prepared for the site visit with insights and to ensure the right parts are loaded onto the truck.

Minimize truck rolls by integrating your systems

Reducing truck rolls has a positive impact, not only on your organizational profits but also on the morale of your support and service teams by improving their efficiency and productivity. Customers are happier too because fast and effective response to their issues means minimal inconvenience and downtime of their broken equipment.

If you can integrate the systems used by your customer care and field service teams, you’ll be well positioned to boost your overall customer experience. In a future blog post, we’ll take a look at how connected appliances and machines can further improve customer experience.